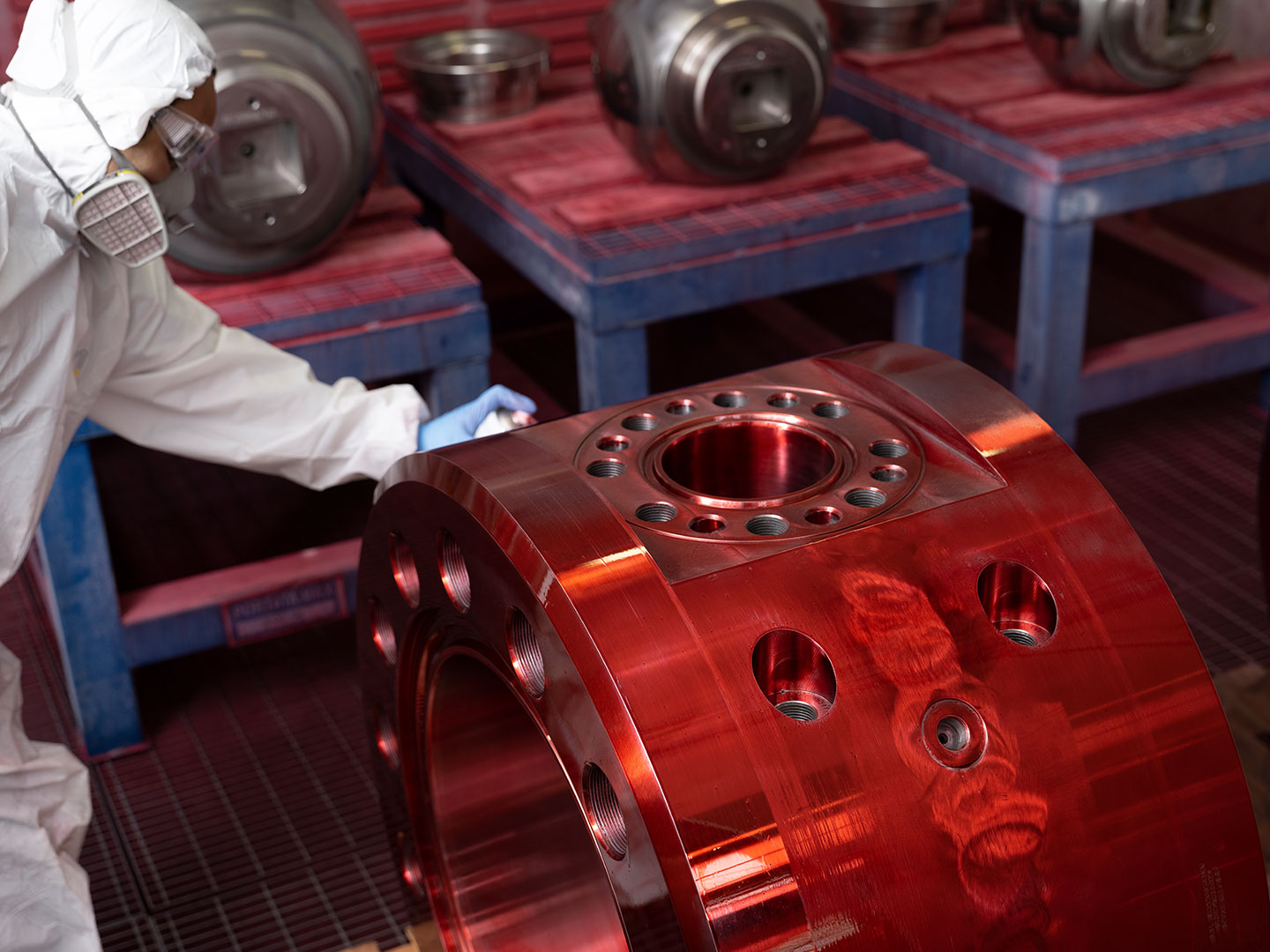

The quality of RMT VM valves is guaranteed by a complete set of non-destructive tests, which allows to verify the properties of every material and components without causing damages.

To make every test as efficient as possible, all our NDE assigned operators are level II certified with the international directive UNI ENISO 9712:2012 and recommended practice SNT-TC-1A, and periodically subjected to upgrading trainings. The full list of operators is available upon request.

They all can perform or supervise the following Non-Destructive Examinations:

- PT Liquid Penetrant Test

- MT Magnetic Particle Test

- UT Ultrasonic Test

- LT Leak Detection Test

- VT Visual Test

- RT – LL Radiographic Test

Testing

RMT valves are 100% tested in our factory.

Our in-house testing capabilities, in addition to the standard requirements of international specification, include:

- High Pressure Nitrogen Test

- Low temperature (cryogenic) shell, seat, and operational test (down to -196°)

- High temperature shell, seat, and operational test (up to 400°C)

- Fugitive Emission Helium Leak Test at low, ambient, and high temperature condition.

- Cycling operational “wear resistance” test

- Torque test

Bending tests, to verify the performance of the valves when subject to bending loads transmitted by piping, have been performed both on side entry and top entry ball valves. Tests included checks of possible body distortion, torque, and leakage rates.